Product Details

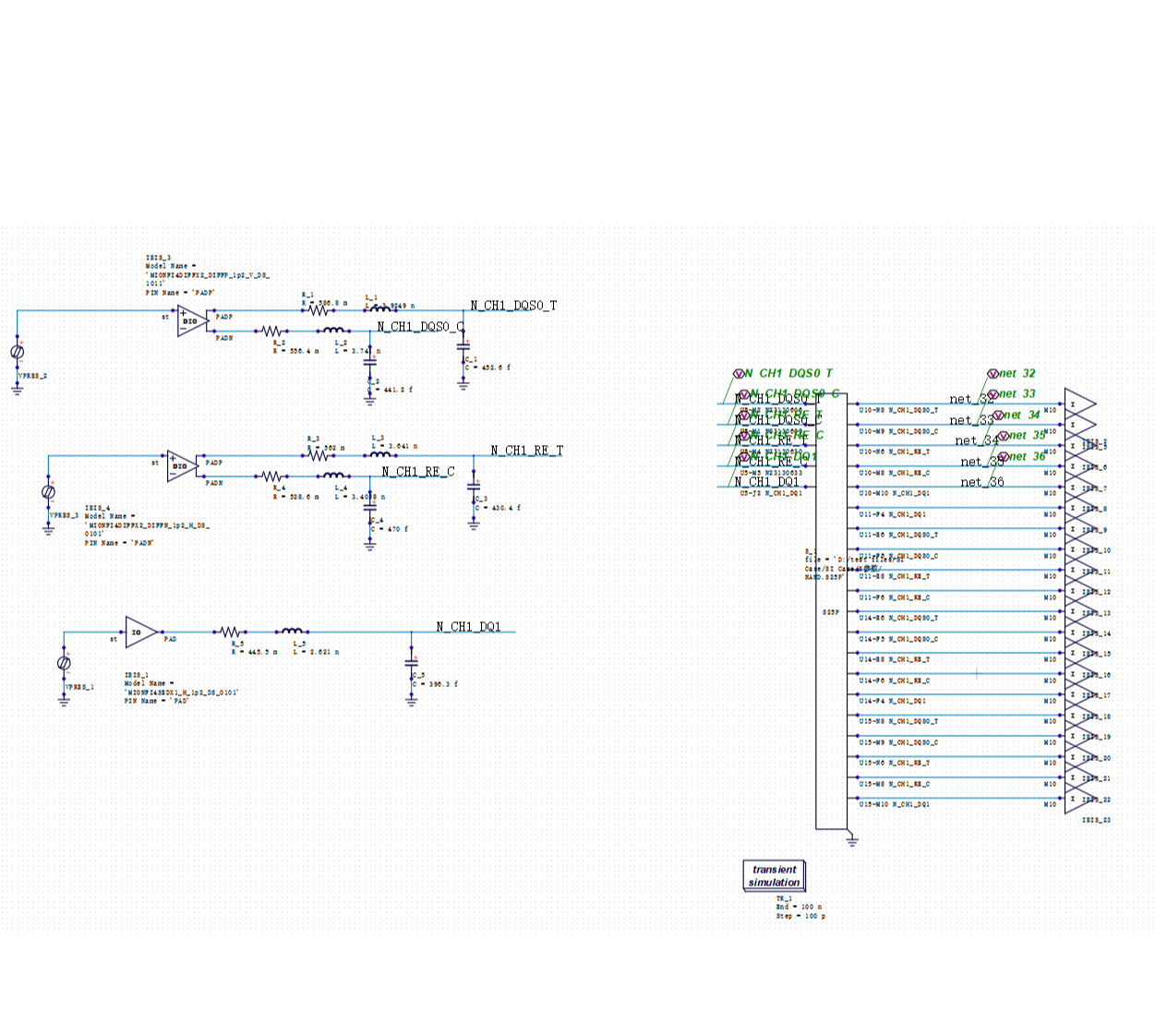

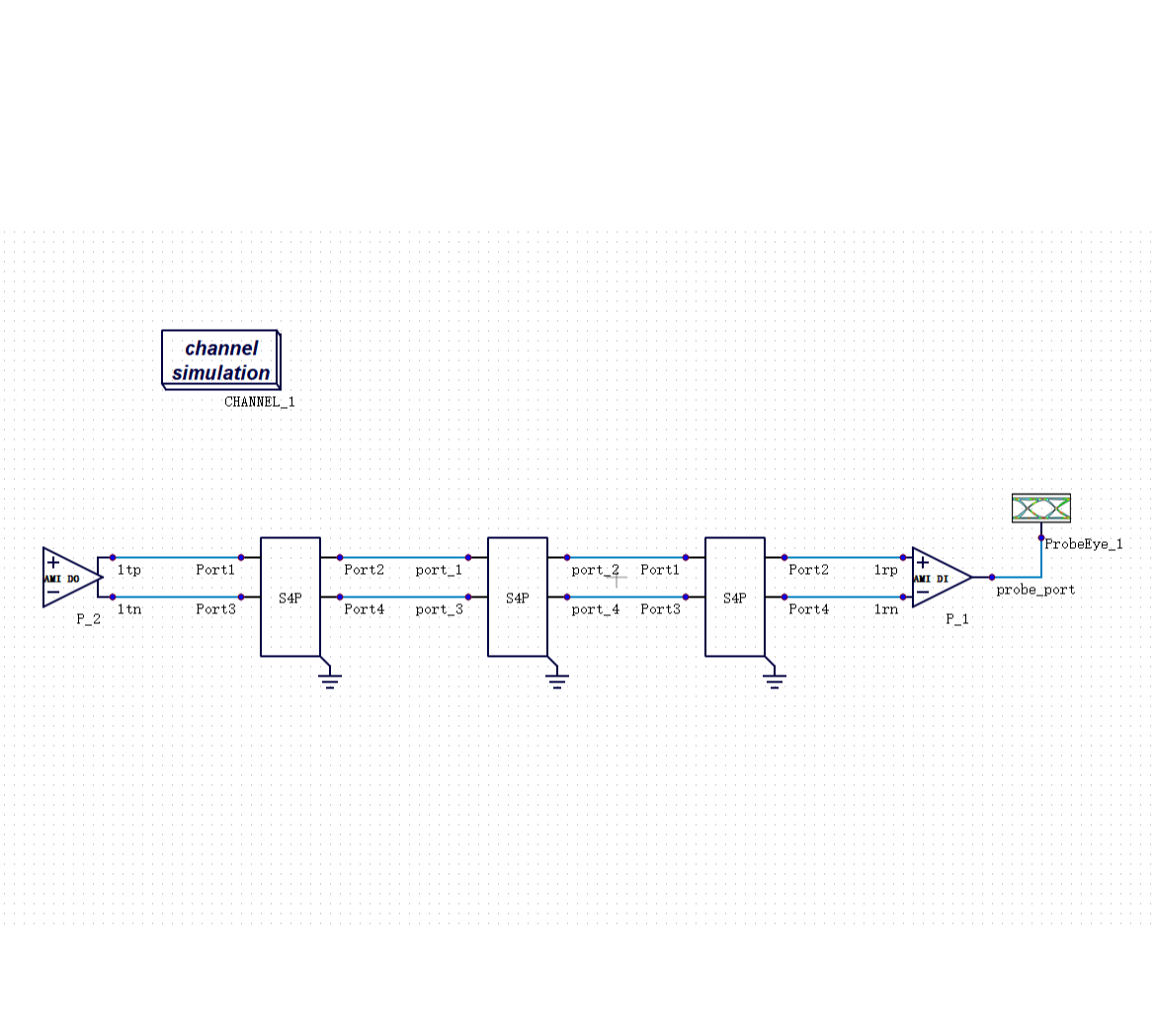

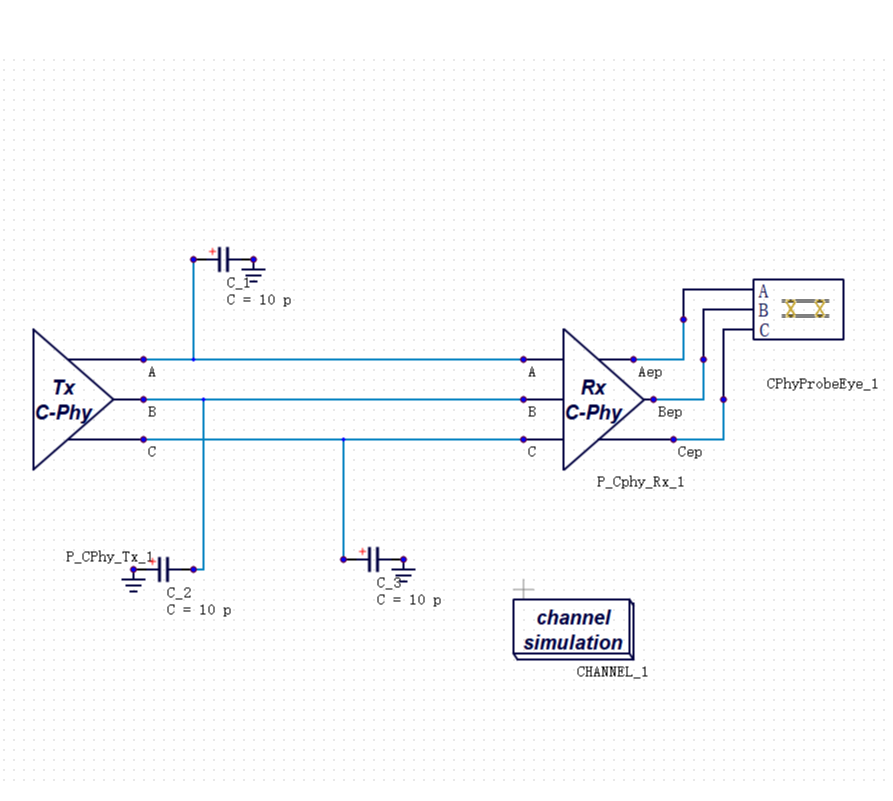

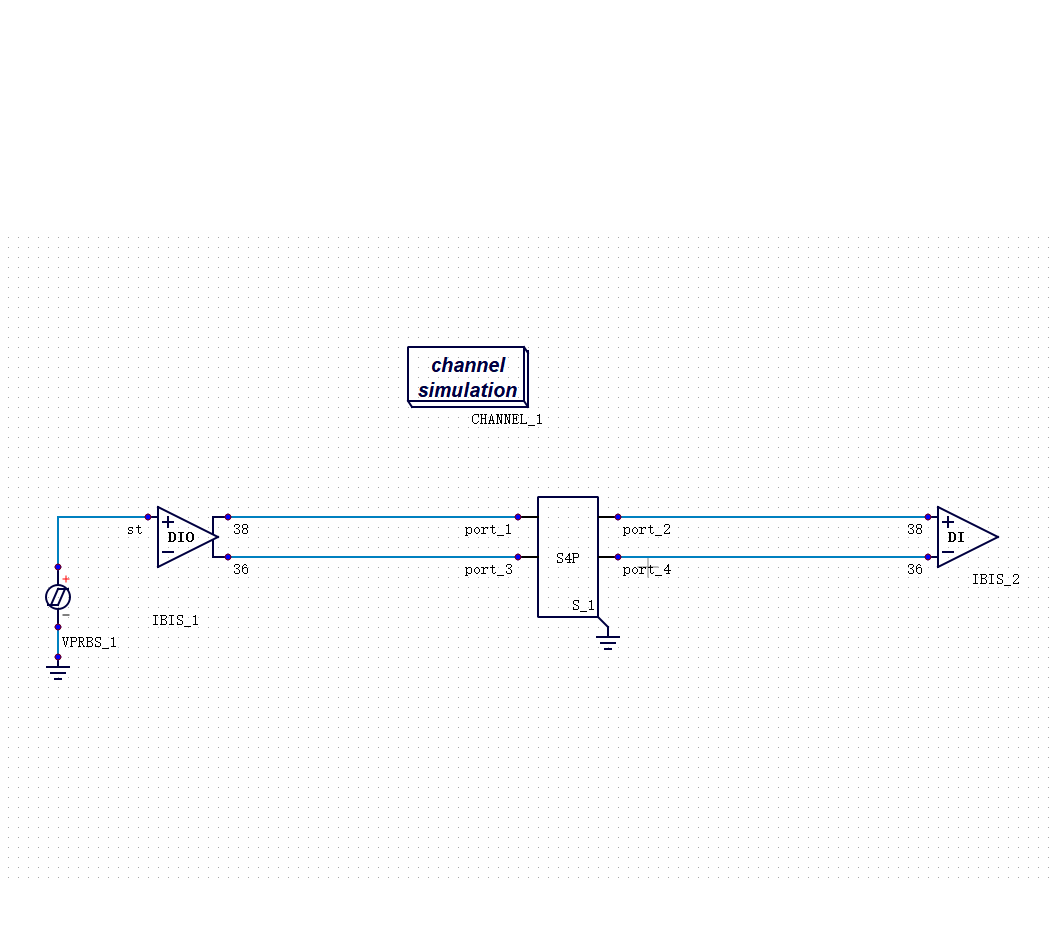

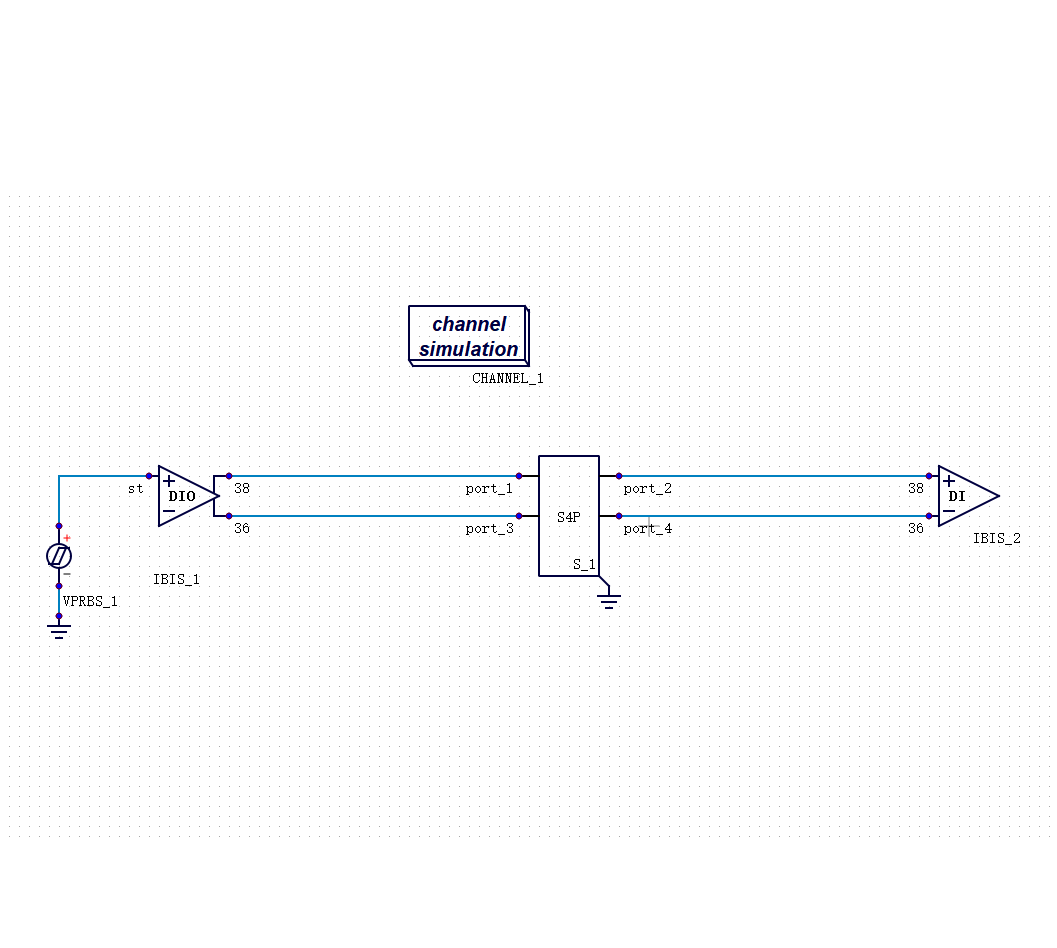

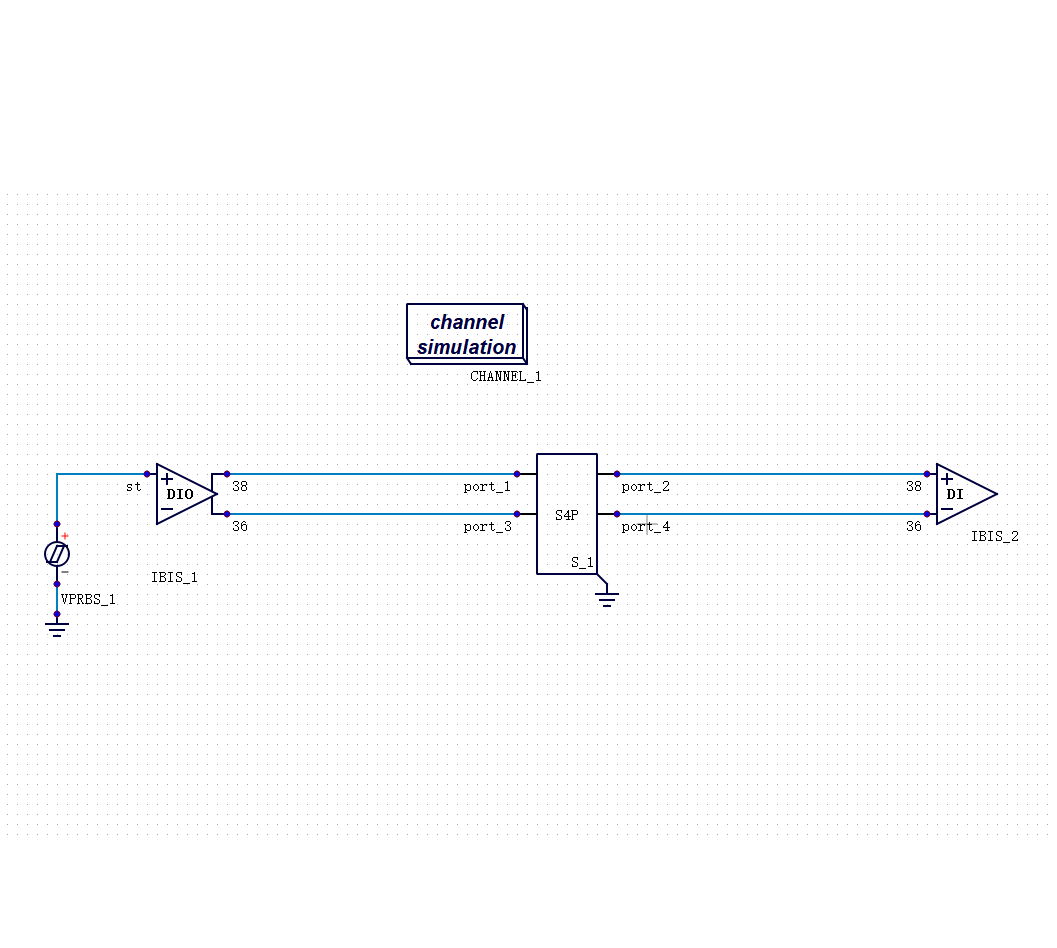

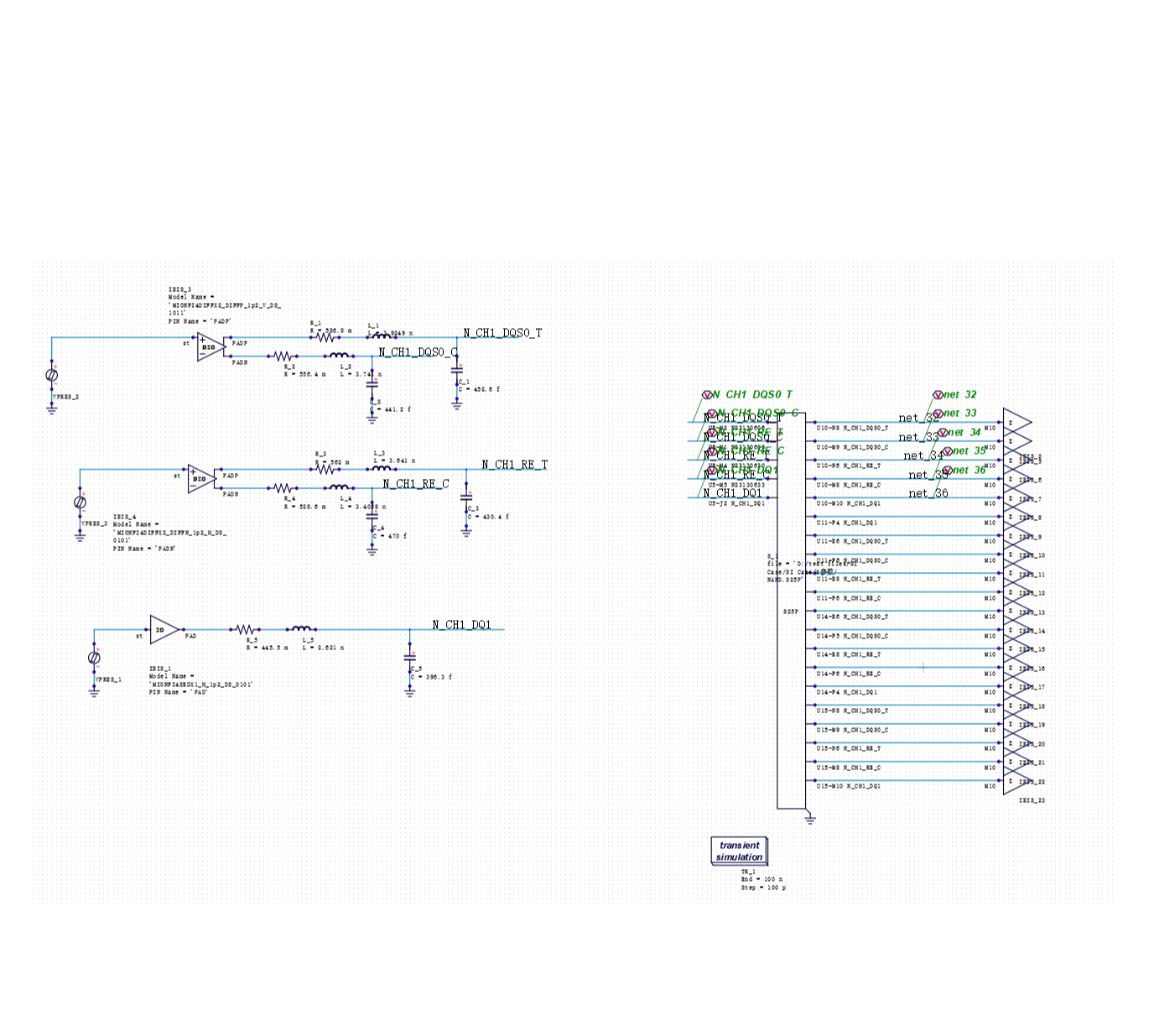

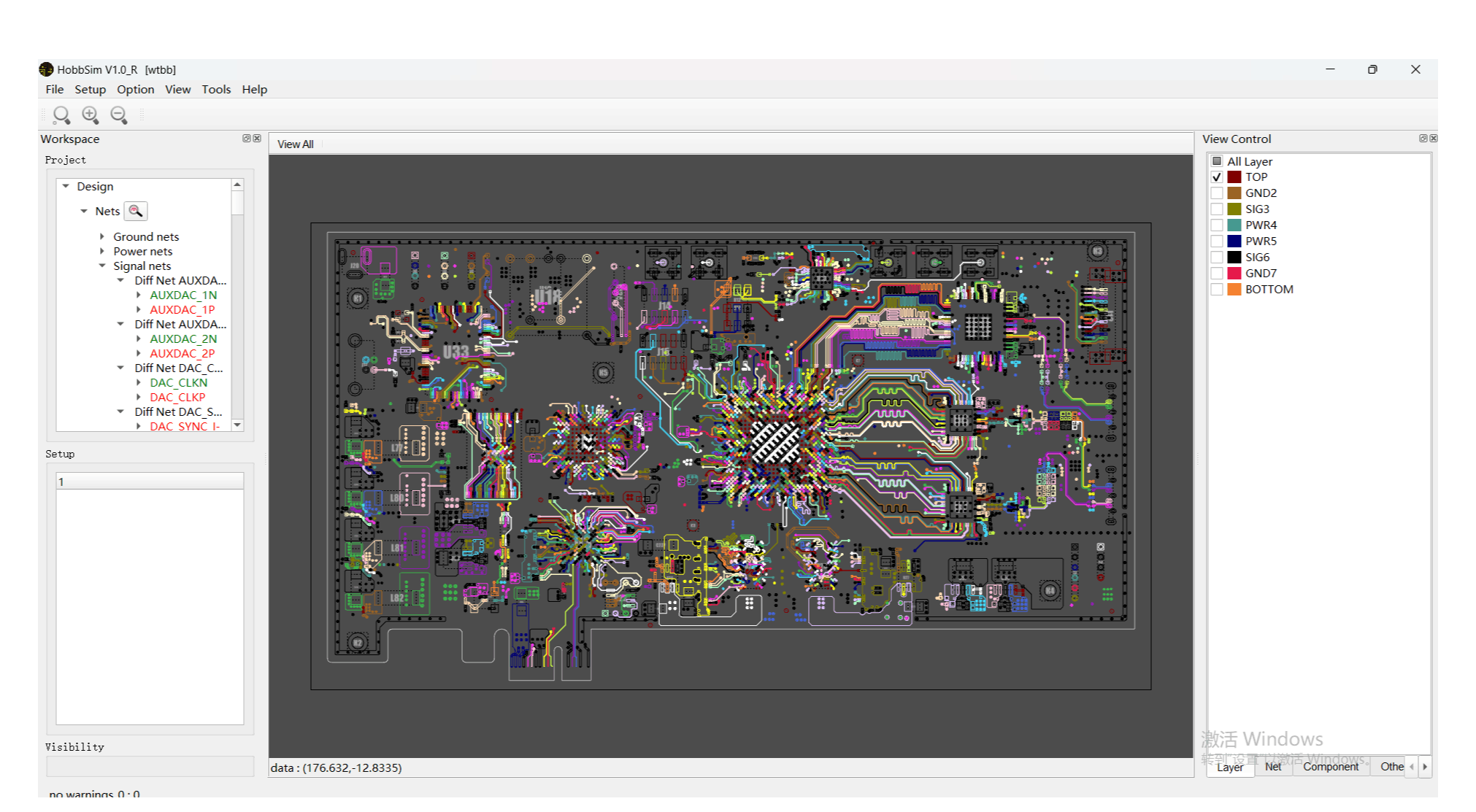

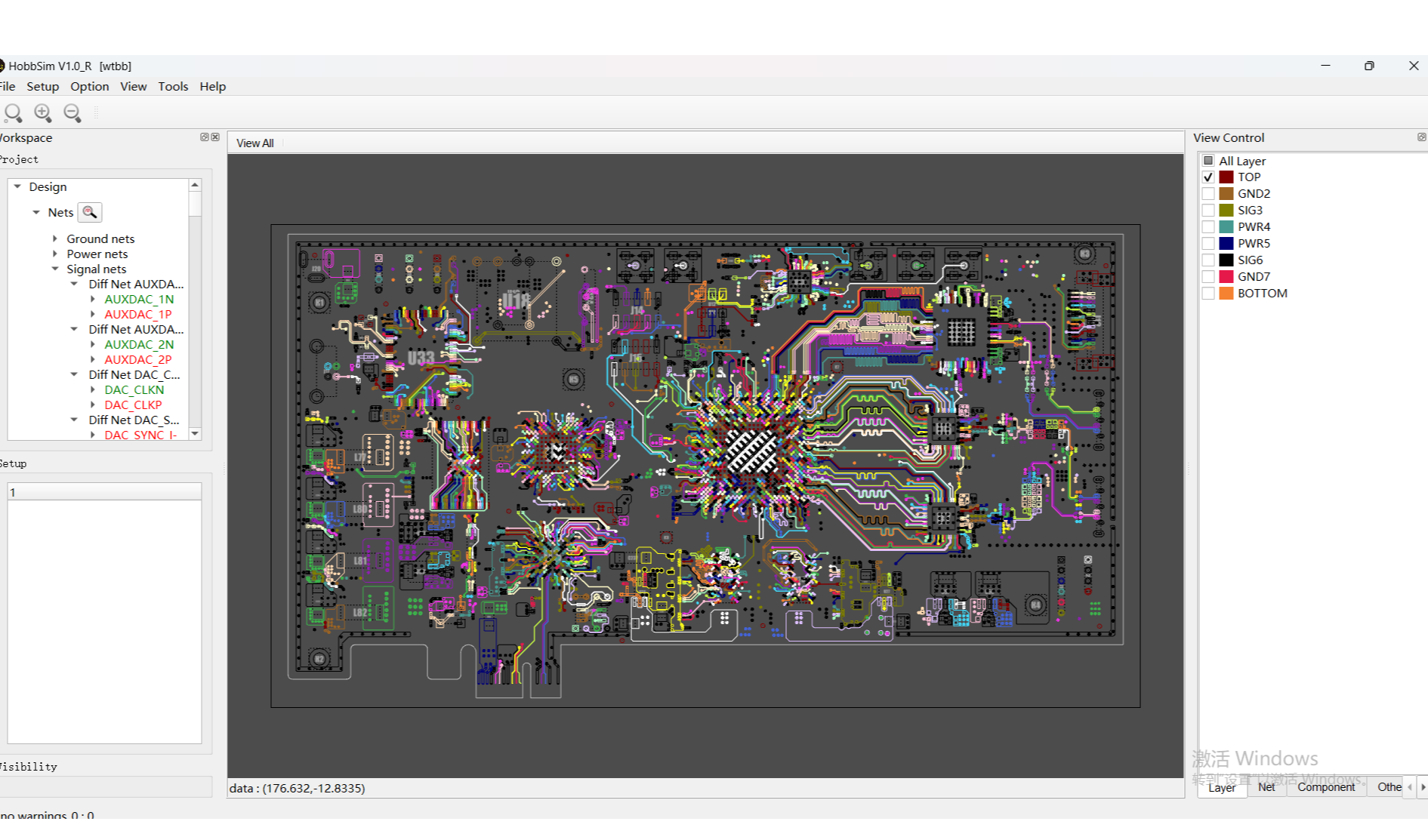

HobbSim is a board-level batch post-simulation tool. It is based on Julin's high-precision simulation engine TJspice, and is designed to solve practical usage pain points for industry-leading customers. It supports parallel (up to 16 cores) simulation of multiple signal lines, batch editing of network models and excitation settings through .xlsx tables, pin selection and soldering, scanning analysis (corner, RLC) and even multi-board cascade simulation. In addition, it supports topology diagram viewing and device modification, definition of cascading, as well as viewing and editing of topology connections, vias, and other information, 2D and 3D viewing, and is even equipped with a content-rich one-click report function (.html) and a feature-rich waveform display. HobbSim is now embedded in the customer's design process, providing an indispensable key node to ensure customer business continuity, and greatly saving the customer's time and labor costs.

Product Function

-

Efficient Signal Processing Functions

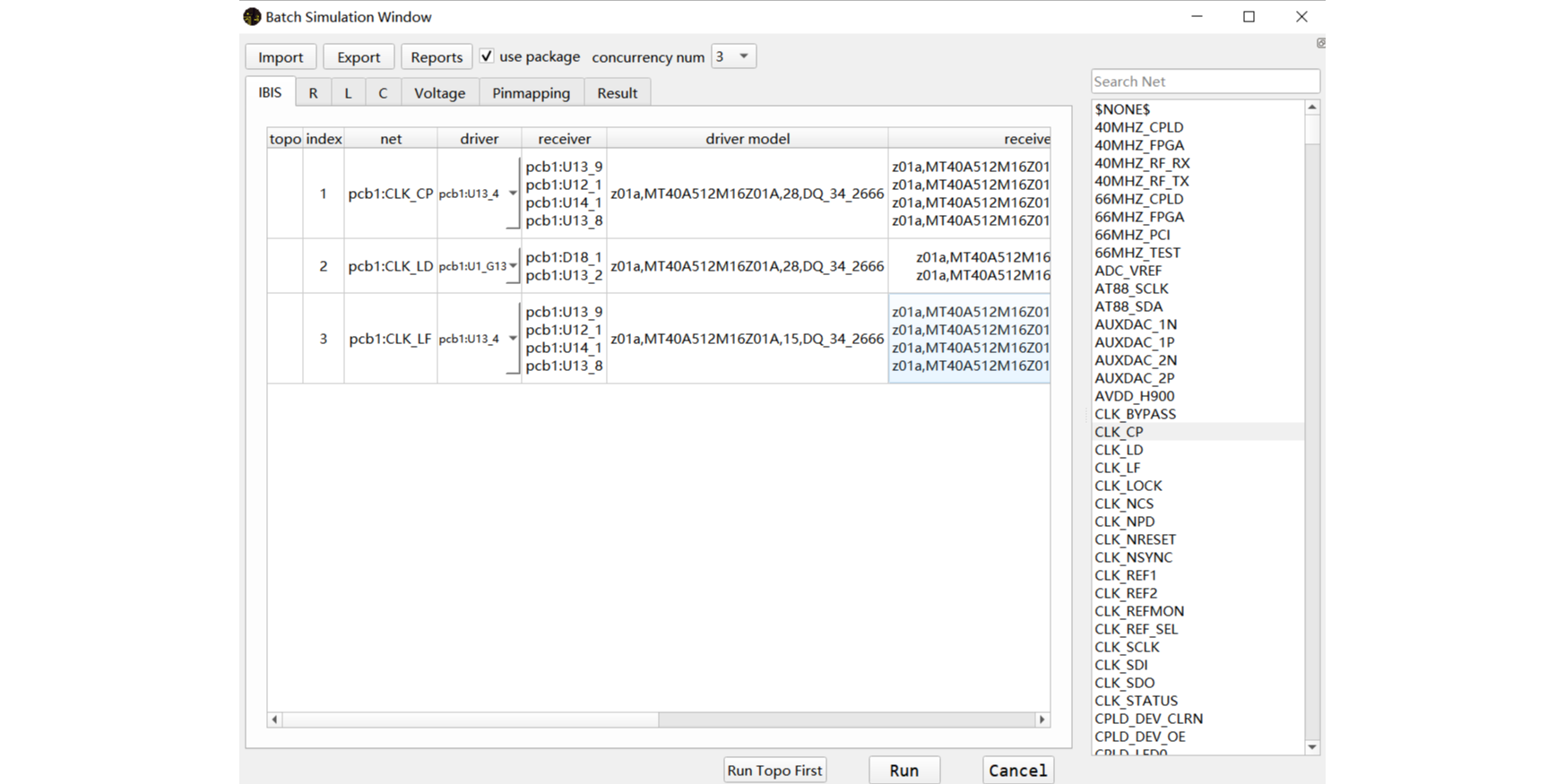

Supports parallel (up to 16 cores) simulation of multiple signal lines

Sweep analysis (corner, RLC)

Batch editing of network models and excitation settings via .xlsx table, selective soldering of pins

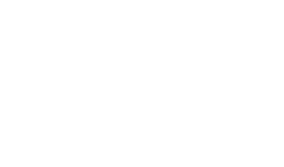

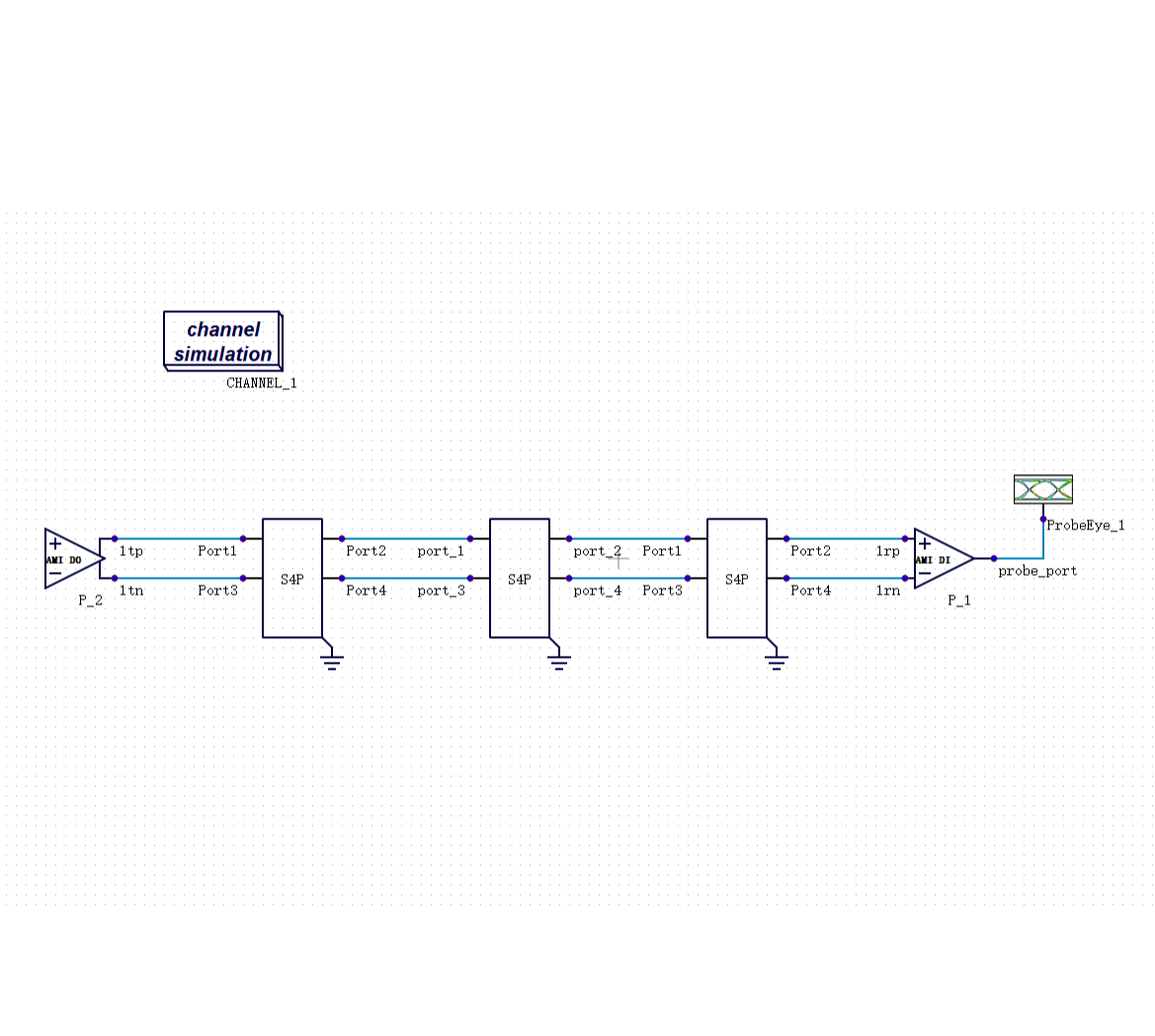

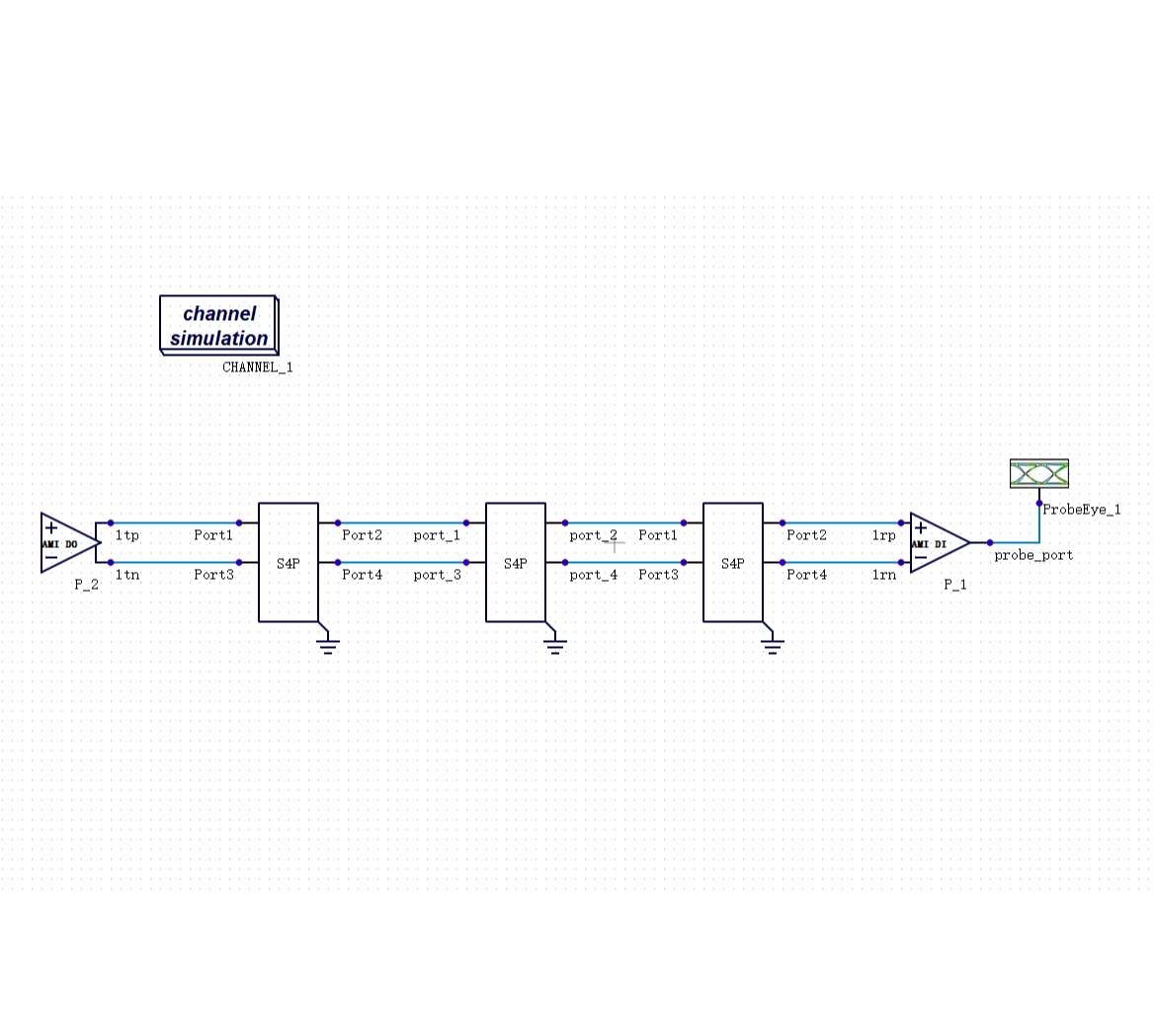

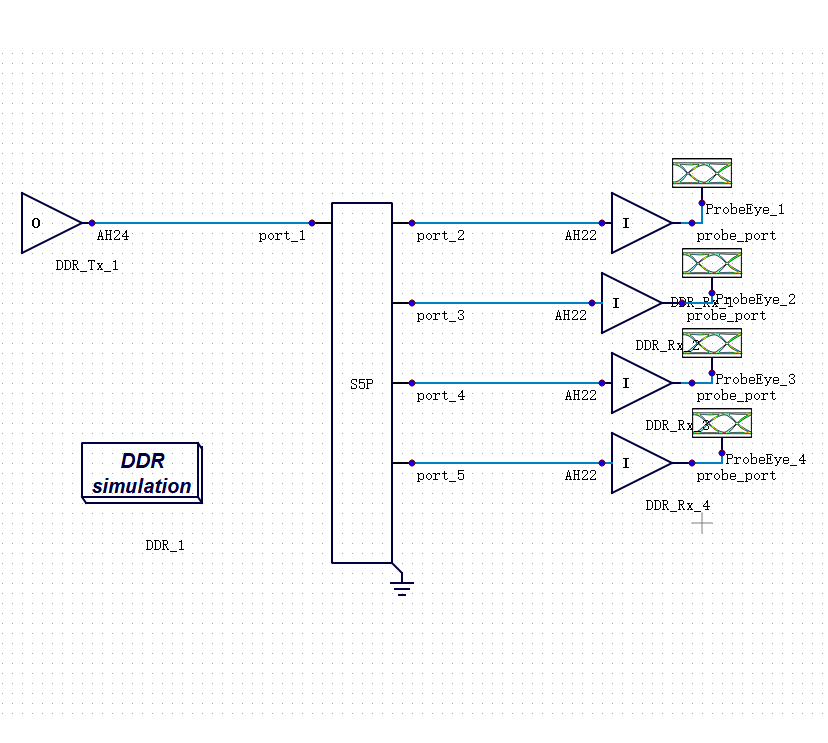

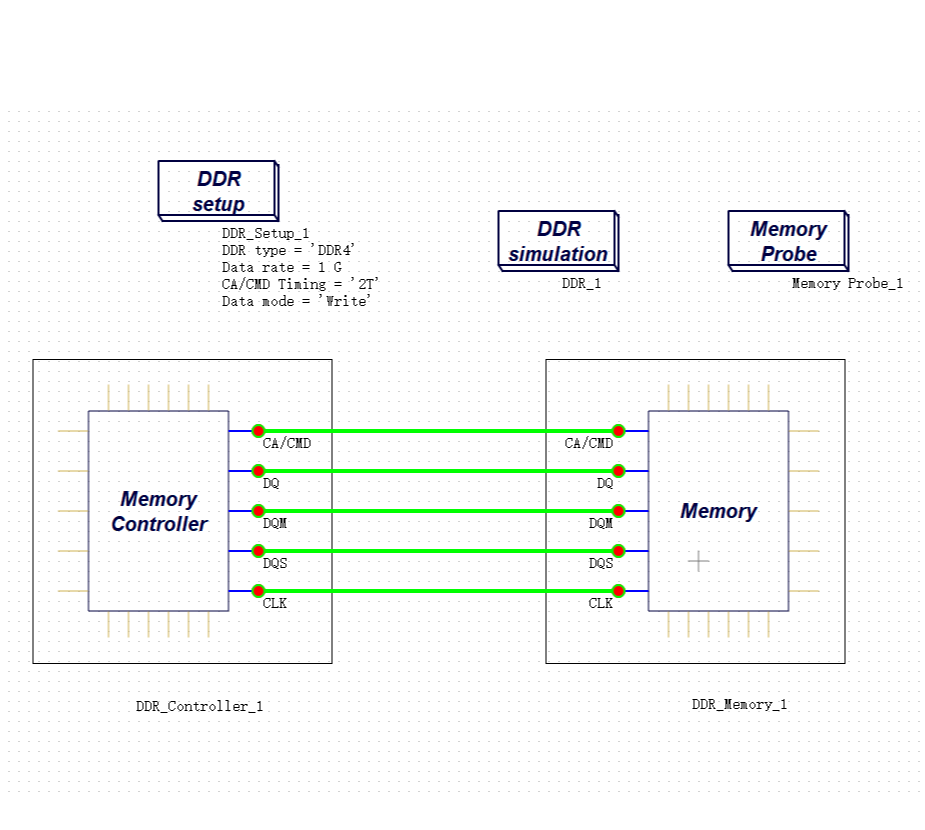

Multi-board cascade simulation

-

-

Flexible multiple viewing and editing options

Supports topology viewing and device editing

2D and 3D viewing

Layer stacking, topology connection, vias and other information viewing and editing

Content-rich one-click report function (.html) and feature-rich waveform display

-

-

Excellent technical accumulation and fast customer response

Based on the high-precision simulation engine TJSPICE, which has been embedded in customers' commercial design flow

focusing on the real needs of industry-leading customers.

-

Video Demo

-

HobbSim Batch Simulation

HobbSim Batch Simulation -

Basic operation of Hobbsim

Basic operation of Hobbsim -

Batch Simulation Using Offline Forms in Hobbsim

Batch Simulation Using Offline Forms in Hobbsim -

HobbSim Multi-Board Cascade Simulation

HobbSim Multi-Board Cascade Simulation

Featured Advantages

-

Batch editing and customization features

Batch edit network model and incentive settings via .xlsx form, flexible adjustment of parameters to adapt to different scenarios.

-

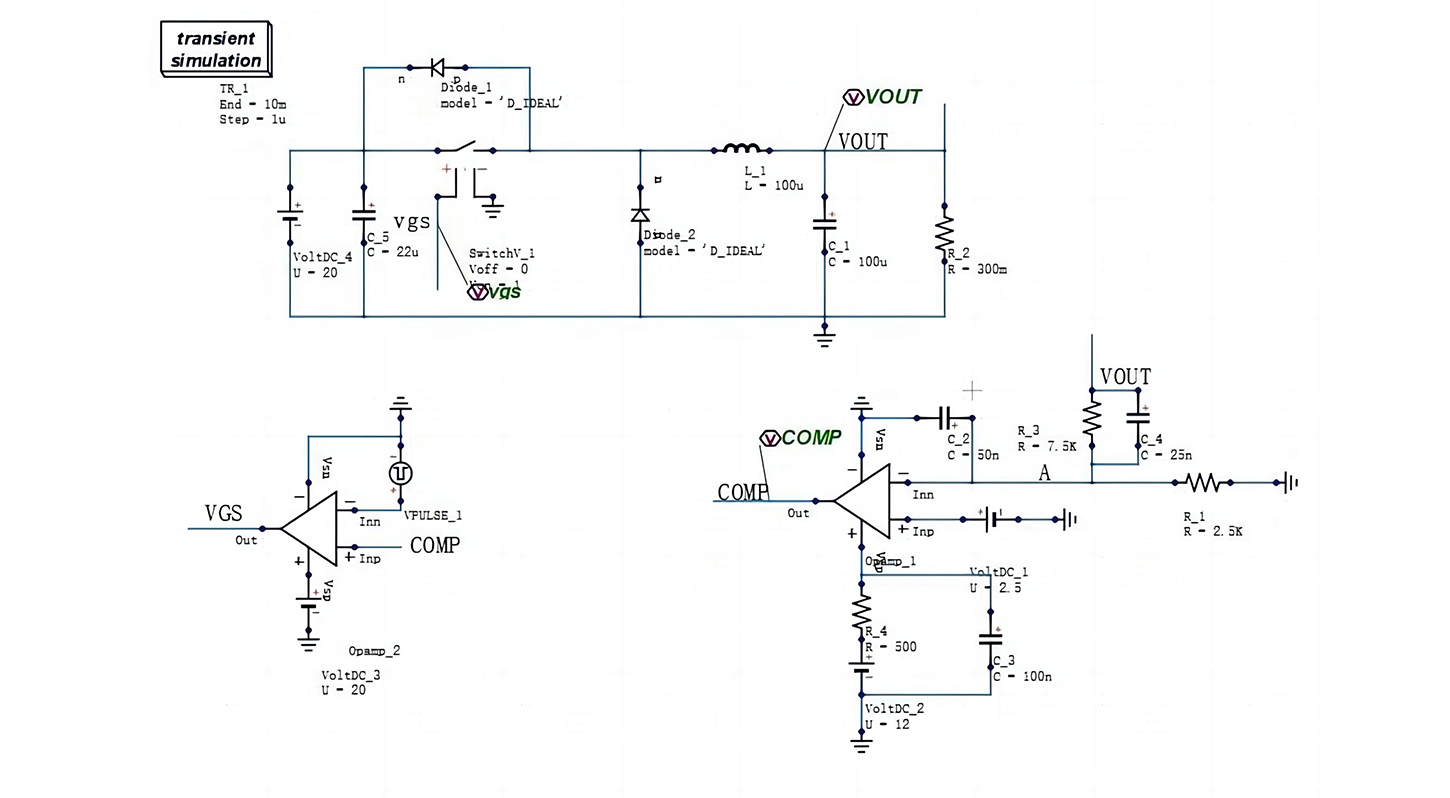

High-precision batch post-simulation technology

Relying on Julin's high-precision simulation engine TJspice, ensures the accuracy of the simulation results and meets the accuracy requirements of industry-leading customers.

-

Detailed information displays and editing

Supports viewing and editing details of layer stacks, topology connections, vias, and other details to enhance design traceability and control.

-

parallel processing capability

Supports parallel simulation from up to 16 cores, significantly improving signal line simulation efficiency and accelerating design iterations.

-

Comprehensive range of simulation types

Support corner, RLC scanning analysis, multi-board cascade simulation, covering from basic to complex circuit simulation needs.

-

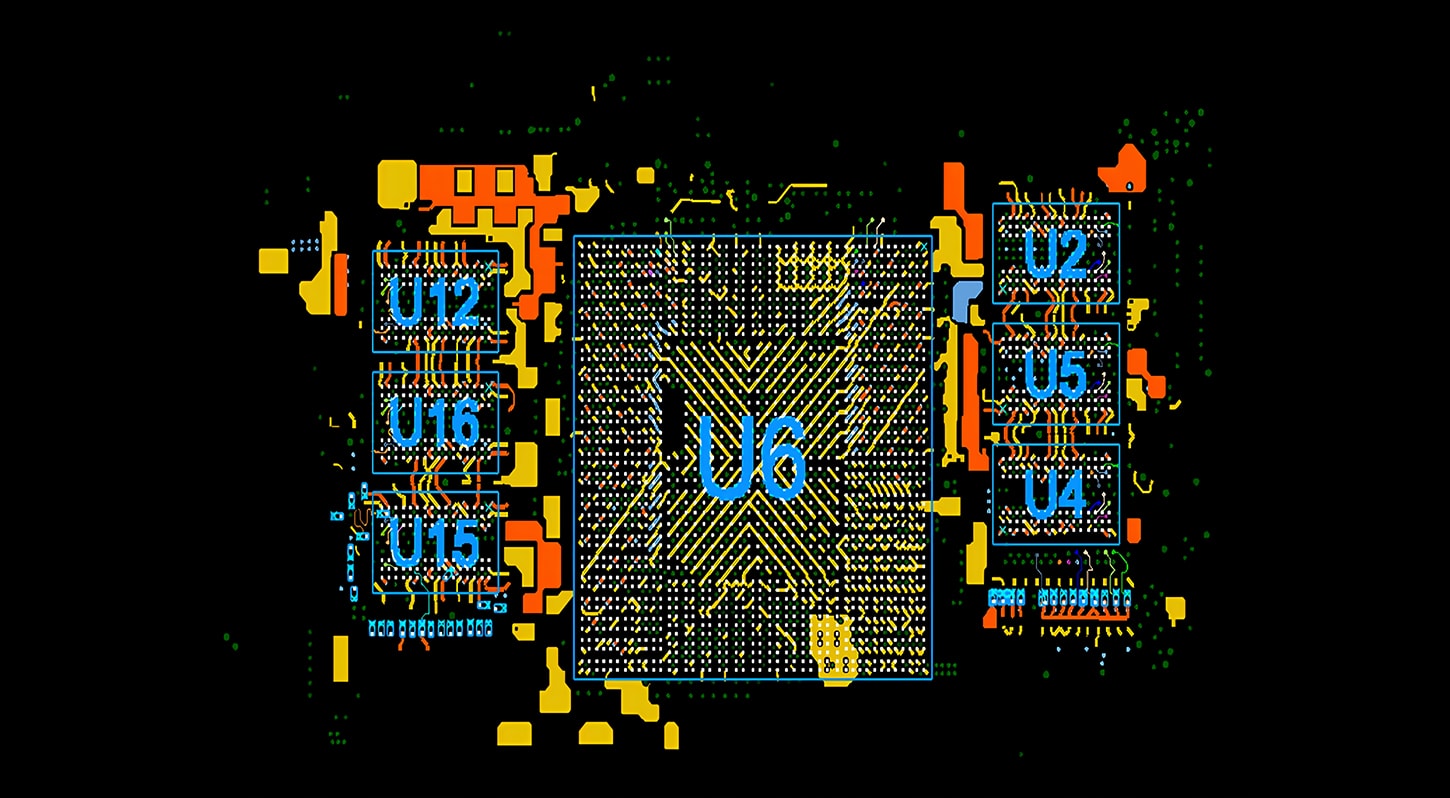

Intuitive topology diagrams and device management

Provides topology view and device editing functions for easy understanding of the circuit structure and optimization of the design.

-

Multi-dimensional view support

Provides 2D and 3D viewing modes to help users understand circuit layout and structure in all aspects.

-

One-click report generation

Equipped with a content-rich one-click report function that automatically generates reports in .html format to simplify document organization.

-

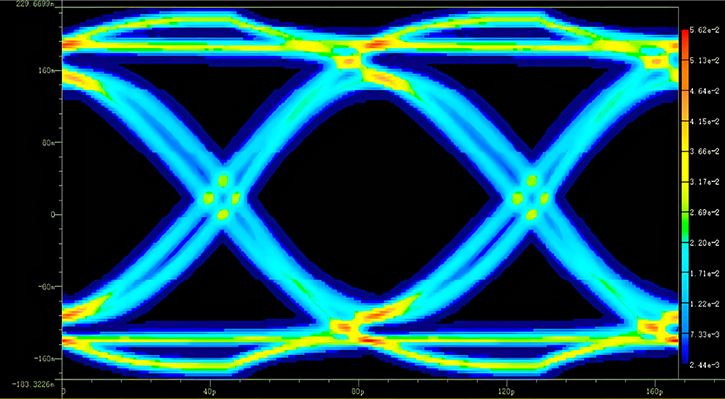

Advanced Waveform Display Tools

Built-in feature-rich waveform display for easy data analysis and troubleshooting.

Product Value

-

Reduce design risk by identifying and resolving issues in advance

Avoid wasted costs: HobbSim provides board-level post emulation to identify signal integrity issues such as reflections, crosstalk, ground bounce, etc. at an early stage of the design. Early detection of these issues avoids the need to re-design and re-board the PCB after it has been boarded.

Shorten the design cycle: By solving signal integrity problems in the simulation phase with HobbSim, the actual debugging time can be reduced, thus shortening the entire design cycle.

-

Improve design reliability and stability

Ensure signal quality: HobbSim analyzes signal timing, amplitude, noise and other parameters to ensure that the signal quality meets the design requirements and improves the reliability and stability of the system.

Optimize PCB layout: HobbSim's simulation results can help optimize PCB layout, such as adjusting the length, spacing, and stacking of wires to reduce signal and power integrity problems.

-

Reduce design costs

Greatly reduce the simulation time and shorten the project cycle: HobbSim's simulation speed is extremely fast, with multi-core parallel simulation can greatly improve the efficiency and shorten the project development and testing cycle from design to board casting.

Reduce debugging time: By verifying the design through HobbSim simulation, the actual debugging time can be reduced, thus reducing debugging cost.

Avoid potential problems: Identifying and solving problems in advance can avoid potential system failures and reduce maintenance costs.

-

Improve design performance

Timing Optimization: HobbSim simulation analysis can optimize the signal timing to increase the operating frequency and data transfer rate of the system.

Reduce Power Consumption: Optimizing PCB design can reduce signal reflection and crosstalk, thus reducing signal energy loss and system power consumption.

Related Industries

-

Product

Details -

Product

Function -

Video

Demo -

Featured

Advantages -

Product

Value -

Related

Industries